Polymer Production Line Feasibility Study

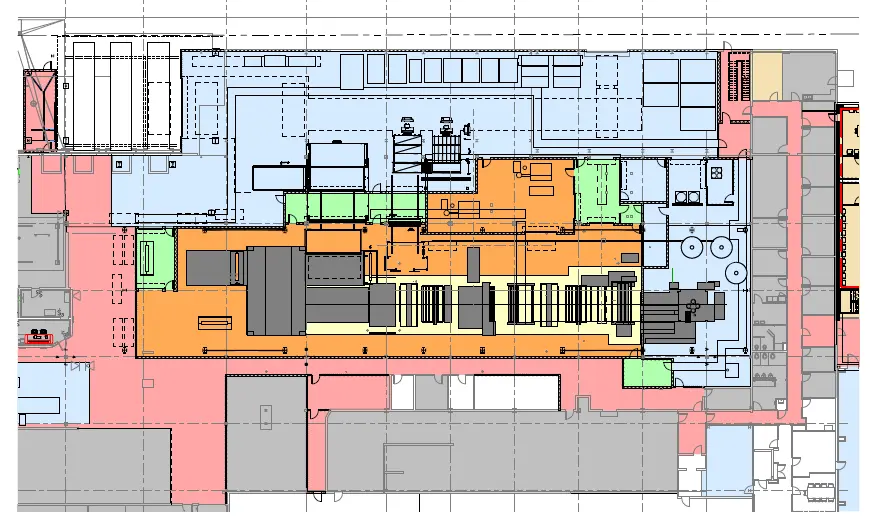

Pickering Associates was tasked with completing a basic engineering/FEL study to evaluate the feasibility of a new polymer extrusion line at an existing manufacturing facility. The overall deliverables of the project included a total project authorization estimate, preliminary layout of production equipment, and vendor coordination to confirm equipment requirements and costs.

PROJECT DETAILS

- Location: Pleasants County, West Virginia

- Type: FEL Study

- Size: 28,750 SF

- Contractor: N/A – FEL Study

PROJECT SERVICES

- Process

- Architecture

- BIM Design

- Electrical Engineering

- Mechanical Engineering

- Structural Engineering

- Piping

- Project Management

Our Process

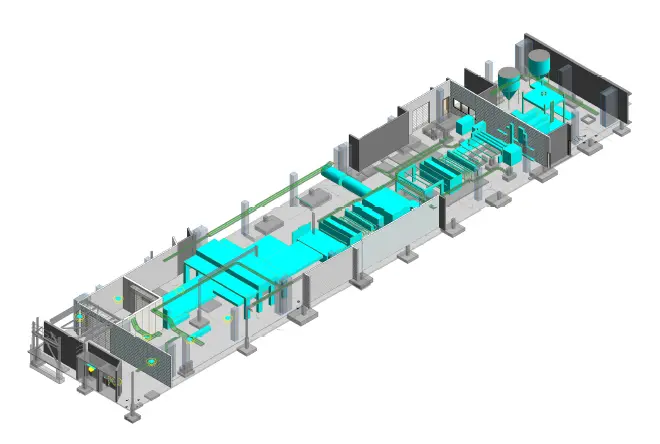

By completing the preliminary design in 3D, all parties were confident the project layout would fit inside the existing area and was optimized for final product flow and worker ergonomics.

This project utilized Pickering Associates IDEA process and BIM capabilities to utilize a project team spread between different sites and included representatives of the Pickering Associates design team, owner representatives, and equipment vendor representatives. By completing the preliminary design in 3D, all parties were confident that not only would the project layout fit inside the existing area, but that it was optimized for final product flow and worker ergonomics.

The cost estimate for this project was compiled using Aspen Capital Cost Estimator and Pickering Associates’ project experience in the field. By utilizing model takeoffs, a very detailed estimate was assembled. By using this method, it allowed not only optimization in building techniques, but also in labor rates and material sourcing. To further develop certainty in the estimate, a gap analysis was performed to identify potential areas and items that could impact the cost estimate. Specialized equipment quotes were able to be loaded and their installation costs incorporated into the estimate.